UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-Q

(Mark One)

| x | QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the quarterly period ended June 30, 2012

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 1-8462

GRAHAM CORPORATION

(Exact name of registrant as specified in its charter)

| Delaware | 16-1194720 | |

| (State or other jurisdiction of incorporation or organization) |

(I.R.S. Employer Identification No.) | |

| 20 Florence Avenue, Batavia, New York | 14020 | |

| (Address of principal executive offices) | (Zip Code) | |

585-343-2216

(Registrant’s telephone number, including area code)

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definition of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| Large accelerated filer | ¨ | Accelerated filer | x | |||

| Non-accelerated filer | ¨ (Do not check if a smaller reporting company) | Smaller reporting company | ¨ | |||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

As of July 27, 2012, there were outstanding 9,977,748 shares of the registrant’s common stock, par value $.10 per share.

Graham Corporation and Subsidiaries

As of June 30, 2012 and March 31, 2012 and for the Three-Month Periods

Ended June 30, 2012 and 2011

| Page | ||||||

| Part I. |

FINANCIAL INFORMATION | |||||

| Item 1. |

Unaudited Condensed Consolidated Financial Statements | 4 | ||||

| Item 2. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations | 16 | ||||

| Item 3. |

Quantitative and Qualitative Disclosure About Market Risk | 26 | ||||

| Item 4. |

Controls and Procedures | 27 | ||||

| Part II. |

OTHER INFORMATION | |||||

| Item 5. |

Other Information | 28 | ||||

| Item 6. |

Exhibits | 30 | ||||

| 31 | ||||||

| 32 | ||||||

2

GRAHAM CORPORATION AND SUBSIDIARIES

FORM 10-Q

JUNE 30, 2012

PART I - FINANCIAL INFORMATION

3

| Item 1. | Unaudited Condensed Consolidated Financial Statements |

GRAHAM CORPORATION AND SUBSIDIARIES

CONDENSED CONSOLIDATED STATEMENTS OF OPERATIONS AND RETAINED EARNINGS

(Unaudited)

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| (Amounts in thousands, except per share data) | ||||||||

| Net sales |

$ | 22,533 | $ | 25,012 | ||||

| Cost of products sold |

16,297 | 16,707 | ||||||

| Cost of goods sold - amortization |

— | 108 | ||||||

|

|

|

|

|

|||||

| Total cost of goods sold |

16,297 | 16,815 | ||||||

|

|

|

|

|

|||||

| Gross profit |

6,236 | 8,197 | ||||||

|

|

|

|

|

|||||

| Other expenses and income: |

||||||||

| Selling, general and administrative |

4,028 | 3,651 | ||||||

| Amortization |

56 | 50 | ||||||

| Interest income |

(11 | ) | (21 | ) | ||||

| Interest expense |

80 | 20 | ||||||

|

|

|

|

|

|||||

| Total other expenses and income |

4,153 | 3,700 | ||||||

|

|

|

|

|

|||||

| Income before provision for income taxes |

2,083 | 4,497 | ||||||

| Provision for income taxes |

693 | 1,481 | ||||||

|

|

|

|

|

|||||

| Net income |

1,390 | 3,016 | ||||||

| Retained earnings at beginning of period |

74,383 | 64,623 | ||||||

| Dividends |

(200 | ) | (198 | ) | ||||

|

|

|

|

|

|||||

| Retained earnings at end of period |

$ | 75,573 | $ | 67,441 | ||||

|

|

|

|

|

|||||

| Per share data |

||||||||

| Basic: |

||||||||

| Net income |

$ | .14 | $ | .30 | ||||

|

|

|

|

|

|||||

| Diluted: |

||||||||

| Net income |

$ | .14 | $ | .30 | ||||

|

|

|

|

|

|||||

| Weighted average common shares outstanding: |

||||||||

| Basic |

10,002 | 9,939 | ||||||

| Diluted |

10,028 | 9,981 | ||||||

| Dividends declared per share |

$ | .02 | $ | .02 | ||||

See Notes to Condensed Consolidated Financial Statements.

4

GRAHAM CORPORATION AND SUBSIDIARY

CONDENSED CONSOLIDATED STATEMENTS OF COMPREHENSIVE INCOME

(Unaudited)

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| (Amounts in thousands, except per share data) | ||||||||

| Net income |

$ | 1,390 | $ | 3,016 | ||||

|

|

|

|

|

|||||

| Other comprehensive income: |

||||||||

| Foreign currency translation adjustment |

(15 | ) | 27 | |||||

| Defined benefit pension and other postretirement plans net of tax of $78 and $35, respectively |

143 | 63 | ||||||

|

|

|

|

|

|||||

| Total other comprehensive income |

128 | 90 | ||||||

|

|

|

|

|

|||||

| Total comprehensive income |

$ | 1,518 | $ | 3,106 | ||||

|

|

|

|

|

|||||

See Notes to Condensed Consolidated Financial Statements.

5

GRAHAM CORPORATION AND SUBSIDIARY

CONDENSED CONSOLIDATED BALANCE SHEETS

(Unaudited)

| June 30, 2012 |

March 31, 2012 |

|||||||

| (Amounts in thousands, except per share data) | ||||||||

| Assets |

||||||||

| Current assets: |

||||||||

| Cash and cash equivalents |

$ | 24,127 | $ | 25,189 | ||||

| Investments |

22,497 | 16,499 | ||||||

| Trade accounts receivable, net of allowances ($25 and $43 at June 30 and March 31, 2012, respectively) |

9,548 | 11,593 | ||||||

| Unbilled revenue |

7,655 | 12,667 | ||||||

| Inventories |

6,625 | 6,047 | ||||||

| Prepaid expenses and other current assets |

576 | 467 | ||||||

| Income taxes receivable |

3,697 | 4,479 | ||||||

| Deferred income tax asset |

37 | 37 | ||||||

|

|

|

|

|

|||||

| Total current assets |

74,762 | 76,978 | ||||||

| Property, plant and equipment, net |

13,296 | 13,453 | ||||||

| Prepaid pension asset |

2,430 | 2,238 | ||||||

| Goodwill |

6,938 | 6,938 | ||||||

| Permits |

10,300 | 10,300 | ||||||

| Other intangible assets, net |

4,923 | 4,968 | ||||||

| Other assets |

100 | 102 | ||||||

|

|

|

|

|

|||||

| Total assets |

$ | 112,749 | $ | 114,977 | ||||

|

|

|

|

|

|||||

| Liabilities and stockholders’ equity |

||||||||

| Current liabilities: |

||||||||

| Current portion of capital lease obligations |

$ | 86 | $ | 85 | ||||

| Accounts payable |

5,970 | 6,303 | ||||||

| Accrued compensation |

4,379 | 4,652 | ||||||

| Accrued expenses and other current liabilities |

3,719 | 3,707 | ||||||

| Customer deposits |

4,169 | 7,257 | ||||||

| Deferred income tax liability |

2,198 | 2,244 | ||||||

|

|

|

|

|

|||||

| Total current liabilities |

20,521 | 24,248 | ||||||

| Capital lease obligations |

181 | 203 | ||||||

| Accrued compensation |

291 | 293 | ||||||

| Deferred income tax liability |

7,454 | 7,404 | ||||||

| Accrued pension liability |

229 | 229 | ||||||

| Accrued postretirement benefits |

904 | 895 | ||||||

| Other long-term liabilities |

72 | 85 | ||||||

|

|

|

|

|

|||||

| Total liabilities |

29,652 | 33,357 | ||||||

|

|

|

|

|

|||||

| Commitments and contingencies (Note 11) |

||||||||

| Stockholders’ equity: |

||||||||

| Preferred stock, $1.00 par value - Authorized, 500 shares |

||||||||

| Common stock, $.10 par value - Authorized, 25,500 shares Issued, 10,324 and 10,297 shares at June 30 and March 31, 2012, respectively |

1,032 | 1,030 | ||||||

| Capital in excess of par value |

17,902 | 17,745 | ||||||

| Retained earnings |

75,573 | 74,383 | ||||||

| Accumulated other comprehensive loss |

(8,032 | ) | (8,160 | ) | ||||

| Treasury stock (346 shares at June 30 and March 31, 2012) |

(3,378 | ) | (3,378 | ) | ||||

|

|

|

|

|

|||||

| Total stockholders’ equity |

83,097 | 81,620 | ||||||

|

|

|

|

|

|||||

| Total liabilities and stockholders’ equity |

$ | 112,749 | $ | 114,977 | ||||

|

|

|

|

|

|||||

See Notes to Condensed Consolidated Financial Statements.

6

GRAHAM CORPORATION AND SUBSIDIARIES

CONDENSED CONSOLIDATED STATEMENTS OF CASH FLOWS

(Unaudited)

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| Operating activities: |

||||||||

| Net income |

$ | 1,390 | $ | 3,016 | ||||

| Adjustments to reconcile net income to net cash provided (used) by operating activities: |

||||||||

| Depreciation |

464 | 353 | ||||||

| Amortization |

56 | 158 | ||||||

| Amortization of unrecognized prior service cost and actuarial losses |

222 | 98 | ||||||

| Discount accretion on investments |

(2 | ) | (3 | ) | ||||

| Stock-based compensation expense |

171 | 134 | ||||||

| Loss on disposal or sale of property, plant and equipment |

3 | — | ||||||

| Deferred income taxes |

(99 | ) | 36 | |||||

| (Increase) decrease in operating assets: |

||||||||

| Accounts receivable |

2,039 | (6,219 | ) | |||||

| Unbilled revenue |

5,012 | 2,164 | ||||||

| Inventories |

(580 | ) | 2,588 | |||||

| Prepaid expenses and other current and non-current assets |

(95 | ) | (373 | ) | ||||

| Prepaid pension asset |

(192 | ) | (208 | ) | ||||

| Increase (decrease) in operating liabilities: |

||||||||

| Accounts payable |

(340 | ) | (2,711 | ) | ||||

| Accrued compensation, accrued expenses and other current and non-current liabilities |

(274 | ) | (989 | ) | ||||

| Customer deposits |

(3,087 | ) | (867 | ) | ||||

| Income taxes payable/receivable |

783 | 1,211 | ||||||

| Long-term portion of accrued compensation, accrued pension liability and accrued postretirement benefits |

6 | 24 | ||||||

|

|

|

|

|

|||||

| Net cash provided (used) by operating activities |

5,477 | (1,588 | ) | |||||

|

|

|

|

|

|||||

| Investing activities: |

||||||||

| Purchase of property, plant and equipment |

(300 | ) | (340 | ) | ||||

| Purchase of investments |

(20,996 | ) | (9,698 | ) | ||||

| Redemption of investments at maturity |

15,000 | 17,320 | ||||||

|

|

|

|

|

|||||

| Net cash (used) provided by investing activities |

(6,296 | ) | 7,282 | |||||

|

|

|

|

|

|||||

| Financing activities: |

||||||||

| Principal repayments on capital lease obligations |

(21 | ) | (17 | ) | ||||

| Issuance of common stock |

— | 66 | ||||||

| Dividends paid |

(200 | ) | (198 | ) | ||||

| Excess tax (deficiency) benefit on stock awards |

(11 | ) | 72 | |||||

|

|

|

|

|

|||||

| Net cash used by financing activities |

(232 | ) | (77 | ) | ||||

|

|

|

|

|

|||||

| Effect of exchange rate changes on cash |

(11 | ) | 22 | |||||

|

|

|

|

|

|||||

| Net (decrease) increase in cash and cash equivalents |

(1,062 | ) | 5,639 | |||||

| Cash and cash equivalents at beginning of year |

25,189 | 19,565 | ||||||

|

|

|

|

|

|||||

| Cash and cash equivalents at end of year |

$ | 24,127 | $ | 25,204 | ||||

|

|

|

|

|

|||||

See Notes to Condensed Consolidated Financial Statements.

7

GRAHAM CORPORATION AND SUBSIDIARIES

NOTES TO CONDENSED CONSOLIDATED FINANCIAL STATEMENTS

(Unaudited)

(Amounts in thousands, except per share data)

NOTE 1 – BASIS OF PRESENTATION:

Graham Corporation’s (the “Company’s”) Condensed Consolidated Financial Statements include (i) its wholly-owned foreign subsidiary located in China and (ii) its wholly-owned domestic subsidiary located in Lapeer, Michigan. The Condensed Consolidated Financial Statements have been prepared in accordance with accounting principles generally accepted in the U.S. (“GAAP”) for interim financial information and the instructions to Form 10-Q and Rule 10-01 of Regulation S-X, each as promulgated by the Securities and Exchange Commission. The Company’s Condensed Consolidated Financial Statements do not include all information and notes required by GAAP for complete financial statements. The unaudited Condensed Consolidated Balance Sheet as of March 31, 2012 presented herein was derived from the Company’s audited Consolidated Balance Sheet as of March 31, 2012. For additional information, please refer to the consolidated financial statements and notes included in the Company’s Annual Report on Form 10-K for the fiscal year ended March 31, 2012 (“fiscal 2012”). In the opinion of management, all adjustments, including normal recurring accruals considered necessary for a fair presentation, have been included in the Company’s Condensed Consolidated Financial Statements.

The Company’s results of operations and cash flows for the three months ended June 30, 2012 are not necessarily indicative of the results that may be expected for the fiscal year ending March 31, 2013 (“fiscal 2013”).

NOTE 2 – REVENUE RECOGNITION:

The Company recognizes revenue on all contracts with a planned manufacturing process in excess of four weeks (which approximates 575 direct labor hours) using the percentage-of-completion method. The majority of the Company’s revenue is recognized under this methodology. The percentage-of-completion method is determined by comparing actual labor incurred to a specific date to management’s estimate of the total labor to be incurred on each contract. Contracts in progress are reviewed monthly, and sales and earnings are adjusted in current accounting periods based on revisions in the contract value and estimated costs at completion. Losses on contracts are recognized immediately when evident. There is no reserve for credit losses related to unbilled revenue recorded for contracts accounted for on the percentage-of-completion method. Any reserve for credit losses related to unbilled revenue is recorded as a reduction to revenue.

Revenue on contracts not accounted for using the percentage-of-completion method is recognized utilizing the completed contract method. The majority of the Company’s contracts have a planned manufacturing process of less than four weeks and the results reported under this method do not vary materially from the percentage-of-completion method. The Company recognizes revenue and all related costs on these contracts upon substantial completion or shipment to the customer. Substantial completion is consistently defined as at least 95% complete with regard to direct labor hours. Customer acceptance is generally required throughout the construction process and the Company has no further material obligations under its contracts after the revenue is recognized.

8

NOTE 3 – INVESTMENTS:

Investments consist solely of fixed-income debt securities issued by the U.S. Treasury with original maturities of greater than three months and less than one year. All investments are classified as held-to-maturity, as the Company has the intent and ability to hold the securities to maturity. The investments are stated at amortized cost which approximates fair value. All investments held by the Company at June 30, 2012 are scheduled to mature between July 5, 2012 and October 25, 2012.

NOTE 4 – INVENTORIES:

Inventories are stated at the lower of cost or market, using the average cost method. For contracts accounted for on the completed contract method, progress payments received are netted against inventory to the extent the payment is less than the inventory balance relating to the applicable contract. Progress payments that are in excess of the corresponding inventory balance are presented as customer deposits in the Condensed Consolidated Balance Sheets. Unbilled revenue in the Condensed Consolidated Balance Sheets represents revenue recognized that has not been billed to customers on contracts accounted for on the percentage-of-completion method. For contracts accounted for on the percentage-of–completion method, progress payments are netted against unbilled revenue to the extent the payment is less than the unbilled revenue for the applicable contract. Progress payments exceeding unbilled revenue are netted against inventory to the extent the payment is less than or equal to the inventory balance relating to the applicable contract, and the excess is presented as customer deposits in the Condensed Consolidated Balance Sheets.

Major classifications of inventories are as follows:

| June 30, 2012 |

March 31, 2012 |

|||||||

| Raw materials and supplies |

$ | 3,071 | $ | 2,366 | ||||

| Work in process |

11,941 | 12,405 | ||||||

| Finished products |

541 | 587 | ||||||

|

|

|

|

|

|||||

| 15,553 | 15,358 | |||||||

| Less - progress payments |

8,928 | 9,311 | ||||||

|

|

|

|

|

|||||

| Total |

$ | 6,625 | $ | 6,047 | ||||

|

|

|

|

|

|||||

9

NOTE 5 – INTANGIBLE ASSETS:

Intangible assets are comprised of the following:

| Gross Carrying Amount |

Accumulated Amortization |

Net Carrying Amount |

||||||||||

| At June 30, 2012 | ||||||||||||

| Intangibles subject to amortization: |

||||||||||||

| Backlog |

$ | 170 | $ | 170 | $ | — | ||||||

| Customer relationships |

2,700 | 277 | 2,423 | |||||||||

|

|

|

|

|

|

|

|||||||

| $ | 2,870 | $ | 447 | $ | 2,423 | |||||||

|

|

|

|

|

|

|

|||||||

| Intangibles not subject to amortization: |

||||||||||||

| Permits |

$ | 10,300 | $ | — | $ | 10,300 | ||||||

| Tradename |

2,500 | — | 2,500 | |||||||||

|

|

|

|

|

|

|

|||||||

| $ | 12,800 | $ | — | $ | 12,800 | |||||||

|

|

|

|

|

|

|

|||||||

| At March 31, 2012 |

||||||||||||

| Intangibles subject to amortization: |

||||||||||||

| Backlog |

$ | 170 | $ | 170 | $ | — | ||||||

| Customer relationships |

2,700 | 232 | 2,468 | |||||||||

|

|

|

|

|

|

|

|||||||

| $ | 2,870 | $ | 402 | $ | 2,468 | |||||||

|

|

|

|

|

|

|

|||||||

| Intangibles not subject to amortization: |

||||||||||||

| Permits |

$ | 10,300 | $ | — | $ | 10,300 | ||||||

| Tradename |

2,500 | — | 2,500 | |||||||||

|

|

|

|

|

|

|

|||||||

| $ | 12,800 | $ | — | $ | 12,800 | |||||||

|

|

|

|

|

|

|

|||||||

Intangible assets are amortized on a straight line basis over the estimated useful lives. Intangible amortization expense for the three months ended June 30, 2012 and 2011 was $45 and $116, respectively. As of June 30, 2012, amortization expense is estimated to be $135 for the remainder of fiscal 2013 and $180 in each of fiscal 2014, fiscal 2015, fiscal 2016 and fiscal 2017.

NOTE 6 – STOCK-BASED COMPENSATION:

The Amended and Restated 2000 Graham Corporation Incentive Plan to Increase Shareholder Value provides for the issuance of up to 1,375 shares of common stock in connection with grants of incentive stock options, non-qualified stock options, stock awards and performance awards to officers, key employees and outside directors; provided, however, that no more than 250 shares of common stock may be used for awards other than stock options. Stock options may be granted at prices not less than the fair market value at the date of grant and expire no later than ten years after the date of grant.

Stock option awards granted in the three months ended June 30, 2012 and 2011 were 49 and 9, respectively. The stock option awards vest 33 1/3% per year over a three-year term. All stock options have a term of ten years from their grant date.

10

Restricted stock awards granted in the three-month periods ended June 30, 2012 and 2011 were 26 and 27, respectively. Performance-vested restricted stock awards granted to officers in fiscal 2013 and fiscal 2012 vest 100% on the third anniversary of the grant date, subject to the satisfaction of the performance metrics established for the applicable three-year period. Time-vested restricted stock awards granted to officers in fiscal 2012 vest 50% on the second anniversary of the grant date and 50% on the fourth anniversary of the grant date. Time-vested restricted stock awards granted to directors in fiscal 2013 and fiscal 2012 vest 100% on the first anniversary of the grant date.

During the three months ended June 30, 2012 and 2011, the Company recognized stock-based compensation costs related to stock option and restricted stock awards of $156 and $116, respectively. The income tax benefit recognized related to stock-based compensation was $55 and $42 for the three months ended June 30, 2012 and 2011, respectively.

The Company has an Employee Stock Purchase Plan (the “ESPP”), which allows eligible employees to purchase shares of the Company’s common stock on the last day of a six-month offering period at a purchase price equal to the lesser of 85 percent of the fair market value of the common stock on either the first day or the last day of the offering period. A total of 200 shares of common stock may be purchased under the ESPP. During the three months ended June 30, 2012 and 2011, the Company recognized stock-based compensation costs of $15 and $18, respectively, related to the ESPP and $5 and $6, respectively, of related tax benefits.

NOTE 7 – INCOME PER SHARE:

Basic income per share is computed by dividing net income by the weighted average number of common shares outstanding for the period. Common shares outstanding include share equivalent units, which are contingently issuable shares. Diluted income per share is calculated by dividing net income by the weighted average number of common shares outstanding and, when applicable, potential common shares outstanding during the period. A reconciliation of the numerators and denominators of basic and diluted income per share is presented below:

11

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| Basic income per share |

||||||||

| Numerator: |

||||||||

| Net income |

$ | 1,390 | $ | 3,016 | ||||

|

|

|

|

|

|||||

| Denominator: |

||||||||

| Weighted common shares outstanding |

9,960 | 9,879 | ||||||

| Share equivalent units (“SEUs”) |

42 | 60 | ||||||

|

|

|

|

|

|||||

| Weighted average common shares and SEUs |

10,002 | 9,939 | ||||||

|

|

|

|

|

|||||

| Basic income per share |

$ | .14 | $ | .30 | ||||

|

|

|

|

|

|||||

| Diluted income per share |

||||||||

| Numerator: |

||||||||

| Net income |

$ | 1,390 | $ | 3,016 | ||||

|

|

|

|

|

|||||

| Denominator: |

||||||||

| Weighted average shares and SEUs outstanding |

10,002 | 9,939 | ||||||

| Stock options outstanding |

26 | 42 | ||||||

|

|

|

|

|

|||||

| Weighted average common and potential common shares outstanding |

10,028 | 9,981 | ||||||

|

|

|

|

|

|||||

| Diluted income per share |

$ | .14 | $ | .30 | ||||

|

|

|

|

|

|||||

Options to purchase a total of 23 and 17 shares of common stock were outstanding at June 30, 2012 and 2011, respectively, but were not included in the above computation of diluted income per share given their exercise prices as they would be anti-dilutive upon issuance.

NOTE 8 – PRODUCT WARRANTY LIABILITY:

The reconciliation of the changes in the product warranty liability is as follows:

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| Balance at beginning of period |

$ | 215 | $ | 202 | ||||

| Expense for product warranties |

11 | 33 | ||||||

| Product warranty claims paid |

(32 | ) | (18 | ) | ||||

|

|

|

|

|

|||||

| Balance at end of period |

$ | 194 | $ | 217 | ||||

|

|

|

|

|

|||||

The product warranty liability is included in the line item “Accrued expenses and other liabilities” in the Condensed Consolidated Balance Sheets.

12

NOTE 9 - CASH FLOW STATEMENT:

Interest paid was $3 and $3 for the three months ended June 30, 2012 and 2011, respectively. In addition, income taxes paid for the three months ended June 30, 2012 and 2011 were $29 and $162, respectively.

During the three months ended June 30, 2012 and 2011, respectively, stock option awards were exercised and restricted stock awards vested. In connection with such stock option exercises and vesting, the related income tax benefit realized exceeded (reduced) the tax benefit that had been recorded pertaining to the compensation cost recognized by $(11) and $72, respectively, for such periods. This excess tax benefit (deficiency) has been separately reported under “Financing activities” in the Condensed Consolidated Statements of Cash Flows.

At June 30, 2012 and 2011, respectively, there were $10 and $63 of capital purchases that were recorded in accounts payable and are not included in the caption “Purchase of property, plant and equipment” in the Condensed Consolidated Statements of Cash Flows. In the three months ended June 30, 2012 and 2011, capital expenditures totaling $0 and $105, respectively, were financed through the issuance of capital leases.

NOTE 10 – EMPLOYEE BENEFIT PLANS:

The components of pension income are as follows:

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| Service cost |

$ | 136 | $ | 115 | ||||

| Interest cost |

357 | 355 | ||||||

| Expected return on assets |

(684 | ) | (678 | ) | ||||

| Amortization of: |

||||||||

| Unrecognized prior service cost |

1 | 1 | ||||||

| Actuarial loss |

252 | 129 | ||||||

|

|

|

|

|

|||||

| Net pension income |

$ | 62 | $ | (78 | ) | |||

|

|

|

|

|

|||||

The Company made no contributions to its defined benefit pension plan during the three months ended June 30, 2012 and does not expect to make any contributions to the plan for the balance of fiscal 2013.

The components of the postretirement benefit income are as follows:

| Three Months Ended June 30, |

||||||||

| 2012 | 2011 | |||||||

| Service cost |

$ | — | $ | — | ||||

| Interest cost |

9 | 11 | ||||||

| Amortization of prior service cost |

(41 | ) | (41 | ) | ||||

| Amortization of actuarial loss |

10 | 9 | ||||||

|

|

|

|

|

|||||

| Net postretirement benefit income |

$ | (22 | ) | $ | (21 | ) | ||

|

|

|

|

|

|||||

13

The Company paid benefits of $1 related to its postretirement benefit plan during the three months ended June 30, 2012. The Company expects to pay benefits of approximately $103 or the balance of fiscal 2013.

NOTE 11 – COMMITMENTS AND CONTINGENCIES:

The Company has been named as a defendant in certain lawsuits alleging personal injury from exposure to asbestos contained in products made by the Company. The Company is a co-defendant with numerous other defendants in these lawsuits and intends to vigorously defend itself against these claims. The claims are similar to previous asbestos suits that named the Company as defendant, which either were dismissed when it was shown that the Company had not supplied products to the plaintiffs’ places of work or were settled for amounts below the expected defense costs. The outcome of these lawsuits cannot be determined at this time.

From time to time in the ordinary course of business, the Company is subject to legal proceedings and potential claims. At June 30, 2012, other than noted above, management was unaware of any other material litigation matters.

NOTE 12 – INCOME TAXES:

The Company files federal and state income tax returns in several domestic and international jurisdictions. In most tax jurisdictions, returns are subject to examination by the relevant tax authorities for a number of years after the returns have been filed. During fiscal 2012, the Company reached a resolution with the U.S. Internal Revenue Service (the “IRS”) with regard to the research and development tax credits claimed during tax years 2006 through 2008. As a result of the resolution, the tax credits claimed were reduced by approximately 40% and interest was assessed on the underpayment of tax. In fiscal 2012, the IRS completed its examination for tax years 2009 and 2010 and proposed an adjustment, plus interest, to disallow all of the research and development tax credits claimed by the Company in those tax years. The Company filed a protest to appeal the adjustment. In May 2012, the Company reached a resolution with the IRS that reduced the research and development tax credits claimed by the Company during tax years 2009 and 2010 by approximately 30%. In the three months ended June 30, 2012, a $24 charge was recorded related to this resolution.

The cumulative tax benefit related to the research and development tax credit for the tax years ended March 31, 1999 through March 31, 2012 was $2,652. The liability for unrecognized tax benefits related to this tax position was $929 and $905 at June 30, 2012 and March 31, 2012, respectively. The net cumulative tax benefit was $1,723 at June 30, 2012. The Company had one additional unrecognized tax benefit of $882 as of March 31, 2012 which was settled during the three months ended June 30, 2012, resulting in a reversal of the liability. Any additional impact on the Company’s income tax liability cannot be determined at this time.

The Company is subject to examination in state and international tax jurisdictions for tax years 2007 through 2011 and tax years 2009 through 2011, respectively. It is the Company’s policy to recognize any interest related to uncertain tax positions in interest expense and any penalties related to uncertain tax positions in selling, general and administrative expense. During the three months ended June 30, 2012 and 2011, the Company recorded $62 and $17, respectively, for interest related to its uncertain tax positions. No penalties related to uncertain tax positions were recorded in the three-month periods ended June 30, 2012 or 2011.

14

NOTE 13 – ACCOUNTING AND REPORTING CHANGES:

In the normal course of business, management evaluates all new accounting pronouncements issued by the Financial Accounting Standards Board (“FASB”), the Securities and Exchange Commission, the Emerging Issues Task Force, the American Institute of Certified Public Accountants or any other authoritative accounting body to determine the potential impact they may have on the Company’s consolidated financial statements.

In June 2011, the FASB amended its guidance related to the presentation of other comprehensive income. The amended guidance requires the presentation of other comprehensive income and its components either (1) together with the components of net income in one continuous statement of comprehensive income or (2) as a separate statement immediately following the statement of income with equal prominence. The provisions of the amended guidance were effective for the Company in the first quarter of fiscal 2013 and the Company elected to present comprehensive income in a separate statement.

In September 2011, the FASB amended its guidance related to the periodic testing of goodwill for impairment. This guidance allows companies to first assess qualitative factors to determine whether the existence of events or circumstances leads to a determination that it is more likely than not that the fair value of a reporting unit is less than its carrying amount. If the entity determines that this threshold is not met, then performing the two-step impairment test may not be necessary. The provisions of the amended guidance were effective for the Company in the first quarter of fiscal 2013. The Company will perform its annual impairment testing of goodwill pursuant to this guidance during the third quarter of fiscal 2013.

Management does not expect any other recently issued accounting pronouncements, which have not already been adopted, to have a material impact on the Company’s consolidated financial statements.

15

| Item 2. | Management’s Discussion and Analysis of Financial Condition and Results of Operations |

(Dollar amounts in thousands, except per share data)

Overview

We are a global business that designs, manufactures and sells custom-engineered ejectors, vacuum systems, condensers, liquid ring pump packages and heat exchangers to the refining and petrochemical industries, and a nuclear code accredited supplier of components and raw materials to the nuclear power generating market. Our equipment is used in critical applications in the petrochemical, oil refining and electric power generation industries, including nuclear, cogeneration and geothermal plants. Our equipment can also be found in alternative energy, including ethanol, biodiesel and coal and gas-to-liquids, as well as other diverse applications, such as metal refining, pulp and paper processing, shipbuilding, (the nuclear propulsion program of the U.S. Navy), water heating, refrigeration, desalination, soap manufacturing, food processing, pharmaceuticals, and heating, ventilating and air conditioning.

Our corporate offices are located in Batavia, New York and we have production facilities in both Batavia, New York and at our wholly-owned subsidiary, Energy Steel & Supply Co., located in Lapeer, Michigan. We also have a wholly-owned foreign subsidiary, Graham Vacuum and Heat Transfer Technology (Suzhou) Co., Ltd., located in Suzhou, China, which supports sales orders from China and provides engineering support and supervision of subcontracted fabrication.

Highlights

Highlights for the three months ended June 30, 2012 (the fiscal year ending March 31, 2013 is referred to as “fiscal 2013”) include:

| • | Net sales for the first quarter of fiscal 2013 were $22,533 a decrease of 10% compared with $25,012 for the first quarter of the fiscal year ended March 31, 2012 (the fiscal year ended March 31, 2012 is referred to as “fiscal 2012”). |

| • | Net income and income per diluted share for the first quarter of fiscal 2013 were $1,390 and $0.14, compared with net income of $3,016 and income per diluted share of $0.30 for the first quarter of fiscal 2012. |

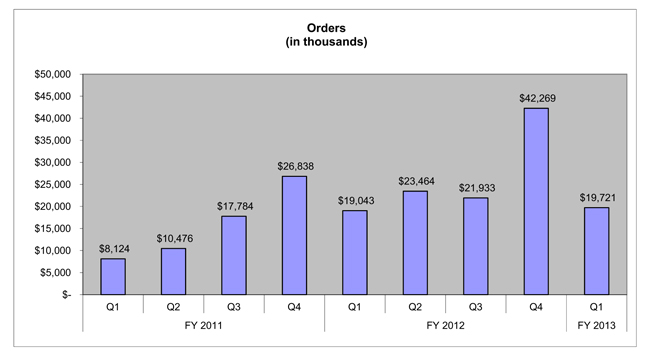

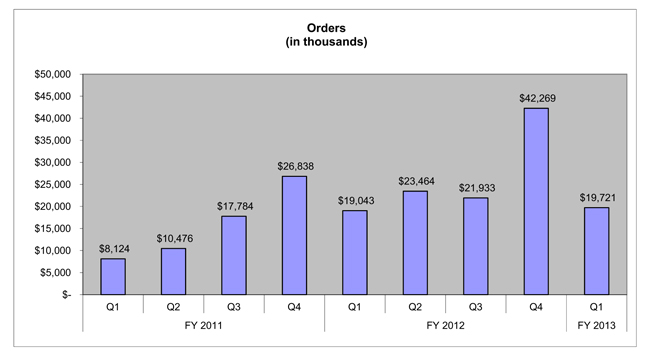

| • | Orders booked in the first quarter of fiscal 2013 were $19,721, up 4% compared with the first quarter of fiscal 2012, when orders were $19,043. |

| • | Backlog decreased to $91,980 at June 30, 2012, representing a 3% decrease compared with March 31, 2012, when backlog was $94,934. |

| • | Gross profit margin and operating margin for the first quarter of fiscal 2013 were 28% and 10%, respectively, compared with 33% and 18%, respectively, for the first quarter of fiscal 2012. |

| • | Cash and short-term investments at June 30, 2012 were $46,624 compared with $41,688 at March 31, 2012. |

Forward-Looking Statements

This report and other documents we file with the Securities and Exchange Commission include “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended.

16

These statements involve known and unknown risks, uncertainties and other factors that may cause actual results to be materially different from any future results implied by the forward-looking statements. Such factors include, but are not limited to, the risks and uncertainties identified by us under the heading “Risk Factors” in Item 1A of our Annual Report on Form 10-K for fiscal 2012.

Forward-looking statements may also include, but are not limited to, statements about:

| • | the current and future economic environments affecting us and the markets we serve; |

| • | expectations regarding investments in new projects by our customers; |

| • | sources of revenue and anticipated revenue, including the contribution from the growth of new products, services and markets; |

| • | plans for future products and services and for enhancements to existing products and services; |

| • | our operations in foreign countries; |

| • | our ability to continue to pursue our acquisition and growth strategy; |

| • | our ability to expand nuclear power work into new markets; |

| • | our ability to successfully execute our existing contracts; |

| • | estimates regarding our liquidity and capital requirements; |

| • | timing of conversion of backlog to sales; |

| • | our ability to attract or retain customers; |

| • | the outcome of any existing or future litigation; and |

| • | our ability to increase our productivity and capacity. |

Forward-looking statements are usually accompanied by words such as “anticipate,” “believe,” “estimate,” “may,” “might,” “intend,” “appear,” “expect” and similar expressions. Actual results could differ materially from historical results or those implied by the forward-looking statements contained in this report.

Undue reliance should not be placed on our forward-looking statements. Except as required by law, we undertake no obligation to update or announce any revisions to forward-looking statements contained in this report, whether as a result of new information, future events or otherwise.

Fiscal 2013 and the Near-Term Market Conditions

The start of fiscal 2013 continues to see active bidding activity. We believe current market conditions are more positive than they have been in the past few years. The business environment in our markets appears to be improving and our customers seem more inclined to move forward with their projects. This supports our belief that our oil refining, petrochemical and related markets remain in the early stages of a business recovery. Nevertheless, there continues to be uncertainty as to whether a sustained global economic recovery is occurring, which in turn continues to affect the timing of new order placement for capital equipment by our customers. This appears to be a timing issue rather than a worsening in our markets.

17

Near-term demand trends that we believe are affecting our customers’ investments include:

| • | As the world recovers from the global recession, many emerging economies continue to have relatively strong economic growth. This expansion is driving growing energy requirements and the need for more refined petroleum products. Although uncertainty in the capital and sovereign debt markets continues, we believe that improved access to capital has resulted in project releases. |

| • | The expansion of the economies of oil producing Middle Eastern countries, their desire to extract greater value from their oil and gas resources, and the continued global growth in demand for oil and refined products has renewed investment activity in that region. We do not believe that the ongoing political unrest in the Middle East has impacted our business. Moreover, the planned timeline of refinery projects in the major Middle Eastern countries is encouraging. |

| • | Asian countries, specifically China and India, are experiencing renewed demand for refined petroleum products such as gasoline. This renewed demand is driving increased investment in petrochemical and refining projects. Although economic growth in Asia appears to be moderating to a lower level, we believe that it remains a fast growing area and Chinese and Indian investments in refining, petrochemical and energy facilities appear to continue to be strong. |

| • | South America, specifically Brazil, Venezuela and Colombia, is seeing increased refining and petrochemical investments that are driven by their expanding economies and increased local demand for gasoline and other products that are made from oil as the feedstock. |

| • | We expect that the U.S. refining markets will not return to the levels experienced during the last up cycle, but that such markets will improve compared with the past few years. We also expect that the U.S. refining markets will continue to be an important aspect of our business. |

| • | We are beginning to see renewed signs of planned investments in the U.S. to convert greater percentages of crude oil to transportation fuels, such as revamping distillation columns to extract residual higher-value components from the low-value waste stream. We are also seeing renewed investment to expand the flexibility of facilities to allow them to utilize multiple feedstocks. |

| • | Investments, including foreign investments, in North American oil sands projects have recently increased, especially for extraction projects in Alberta. Such investments suggest that downstream spending involving our equipment might increase in the next one to three years. |

| • | The recent dramatic reduction in natural gas costs in the U.S. has led to a revival in the U.S. petrochemical market and a recent interest toward potential major investment. There are numerous projects in planning or initial engineering phases for the construction of new petrochemical producing facilities, including ethylene, ammonia and urea. We historically have had strong market share within these facilities. Proposed ethylene capacity expansion and re-opening of mothballed facilities, in the U.S., as well as downstream products, are also being discussed by petrochemical producers for the first time in well over a decade. Lower natural gas costs is a relatively recent phenomena, having occurred over the past three years and is driven by technology advancements in drilling, creating a significant increase in supply. This has made the U.S. production of raw material for ethylene, ethane (which is a side product of natural gas production) globally competitive with naphtha (the alternative feedstock for ethylene used in most of the world). We believe that future investment in U.S. petrochemical markets could be significant. |

18

| • | Investment in new nuclear power capacity internationally may become subject to increased uncertainty due to political and social pressures, which were augmented by the tragic earthquake and tsunami that occurred in Japan in March 2011. The need for additional safety and back up redundancies at the 104 existing domestic nuclear plants could increase demand for Energy Steel’s products in the near-term. |

| • | Investments in existing U.S. nuclear plants to extend their operating life and add incremental capacity are expected to continue. |

| • | Investment in new U.S. nuclear reactor projects planned for the Summer (South Carolina) and Vogtle (Georgia) facilities suggest continued growth in the domestic nuclear market, although such growth may be slowed by the perceptions related to the Fukushima accident in Japan and the potential impact of increased use of natural gas for power generation. |

We expect that the consequences of these near-term trends, and specifically projected expansion in petrochemical and oil refining outside of North America, primarily in the growing Asian and South American markets, will result in more pressure on our pricing and gross margins, as these markets historically provided lower margins than North American refining markets. A potential offset to margin pressure from international markets may come from investments in new petrochemical capacity built in North America and the timing of such investments.

Because of continued global economic and financial uncertainty and the risk associated with growth in emerging economies, we also expect that we will have continued volatility in our order pattern. We continue to expect our new order levels to remain volatile, resulting in both strong and weak quarters. Quarterly orders can vary significantly as indicated in the following chart which depicts our quarterly order levels for the first quarter of fiscal 2013 as well as the four quarters of fiscal 2012 and fiscal 2011.

19

We believe that looking at our order level in any one quarter does not provide an accurate indication of our future expectations or performance. Rather, we believe that looking at our orders and backlog over a one-to two-year period provides a better measure of our business. In the near future, we expect to see smaller value projects than what we had seen during the last expansion cycle. This will require more orders for us to achieve a similar revenue level and will adversely impact our ability to realize margin gains through volume leverage.

Mix Shift: Expected Stronger International Growth in Refining and Chemical Processing with Domestic Growth in Nuclear Power and U.S. Navy Projects

We expect growth in the refining and chemical processing markets to be driven by emerging markets. We have also expanded our addressable markets through the acquisition of Energy Steel and our focus on U.S. Navy nuclear propulsion projects. We believe our revenue opportunities during the near term will be equivalent between the domestic and international markets.

Over the long-term, we expect our customers’ markets to regain their strength and, while remaining cyclical, continue to grow. We believe the long-term trends remain strong and that the drivers of future growth include:

Long-term Demand Trends

| • | Global consumption of crude oil is estimated to expand significantly over the next two decades, primarily in emerging markets. This is expected to offset estimated flat to slightly declining demand in North America and Europe. In addition, an increased trend toward export supply of finished product from the Middle East to North America and Europe is expected. |

| • | Global oil refining capacity is projected to increase, and is expected to be addressed through new facilities, refinery upgrades, revamps and expansions. |

| • | Increased demand is expected for power, refinery and petrochemical products, stimulated by an expanding middle class in Asia, South America and the Middle East. |

| • | Increased development of geothermal electrical power plants in certain regions is expected to address projected growth in demand for electrical power. |

| • | Increased global regulations over the refining, petrochemical and nuclear power industries are expected to continue to drive requirements for capital investments. |

| • | More refineries are expected to convert their facilities to use heavier, more readily available and lower cost crude oil as a feedstock. |

| • | Shale gas development and the resulting increase in available low cost natural gas in the U.S. may change the power landscape. This may drive more future investment in natural gas or combined cycle power plants and possibly away from planned nuclear. |

| • | The lower cost of natural gas and its by-product, ethane, may lead to renewed investment in North American based chemical/petrochemical facilities to meet domestic needs. Ethane, as a feedstock to ethylene production, is now at a cost advantage to naphtha, the oil-based feedstock for ethylene production used in much of the rest of the world. Because of this cost competitive position of ethane, the opportunity to invest in North American chemical/petrochemical plants is possible for the first time in well over a decade. |

20

| • | Construction of new petrochemical plants in the Middle East are planned to meet increased local demand. |

| • | Increased focus on safety and redundancy is anticipated in existing nuclear power facilities. |

| • | Long-term increased project development of international nuclear facilities is expected, despite the recent tragedy in Japan, (including in the U.S.). |

| • | Increased investments in new power generation projects are expected in Asia and South America to meet projected consumer demand increases. |

| • | Long-term growth potential is believed to exist in alternative energy markets, such as geothermal, coal-to-liquids, gas-to-liquids and other emerging technologies, such as biodiesel, and waste-to-energy. |

We believe that all of the above factors offer us long-term growth opportunities to meet our customers’ expected capital project needs. In addition, we believe we can continue to grow our less cyclical smaller product lines and aftermarket businesses.

Our domestic sales, as a percentage of aggregate product sales, in the first quarter of fiscal 2013 were 56%. This continues the trend from fiscal 2012 where domestic sales had increased to 54% of total sales, up from 45% in fiscal 2010 and 2011. The increase in domestic sales has been due to our acquisition of Energy Steel in late fiscal 2011, which primarily has a domestic customer base, and the conversion of the U.S. Navy order. The Navy activity represents our production of surface condensers for the CVN-79 Gerald R. Ford Class nuclear carrier order that was won in the third quarter of our fiscal year ended March 31, 2010.

Results of Operations

For an understanding of the significant factors that influenced our performance, the following discussion should be read in conjunction with our condensed consolidated financial statements and the notes to our condensed consolidated financial statements included in Part I, Item 1, of this Quarterly Report on Form 10-Q.

The following table summarizes our results of operations for the periods indicated:

| Three Months Ended June 30, | ||||||||

| 2012 | 2011 | |||||||

| Net sales |

$ | 22,533 | $ | 25,012 | ||||

| Net income |

$ | 1,390 | $ | 3,016 | ||||

| Diluted income per share |

$ | 0.14 | $ | 0.30 | ||||

| Total assets |

$ | 112,749 | $ | 118,195 | ||||

21

The First Quarter of Fiscal 2013 Compared With the First Quarter of Fiscal 2012

Sales for the first quarter of fiscal 2013 were $22,533, a 10% decrease as compared with sales of $25,012 for the first quarter of fiscal 2012. The decrease in the current quarter’s sales was driven by lower volume in the refining market, which had a large Mideast project convert in the first half of fiscal 2012. International sales year-over-year decreased $3,851, or 28%, due to decreases of $5,188 in the Middle East and $2,324 in South America, partly offset by higher Canadian sales, which were up $2,940. International sales accounted for 44% and 55% of total sales for the first quarter of fiscal 2013 and fiscal 2012, respectively. Domestic sales increased $1,372, or 12%, in the first quarter of fiscal 2013 compared with the first quarter of fiscal 2012. Fluctuations in sales among products and geographic locations can vary measurably from quarter-to-quarter based on timing and magnitude of projects. Sales in the three months ended June 30, 2012 were 23% to the refining industry, 25% to the chemical and petrochemical industries, 23% to the power industry, including the nuclear market and 29% to other commercial and industrial applications. Sales in the three months ended June 30, 2011 were 48% to the refining industry, 12% to the chemical and petrochemical industries, 23% to the power industry, and 17% to other commercial and industrial applications. For additional information on future sales and our markets, see “Orders and Backlog” below.

Our gross profit margin for the first quarter of fiscal 2013 was 28% compared with 33% for the first quarter of fiscal 2012. Gross profit dollars for the first quarter of fiscal 2013 decreased 24% compared with fiscal 2012, to $6,236 from $8,197. Gross profit percentage and dollars decreased primarily due to lower volume / capacity utilization and conversion of projects which had less favorable pricing compared with the projects converted in the first quarter of fiscal 2012. Certain projects which converted in the first quarter of the prior fiscal year were won during the prior market peak, where pricing was strong.

Selling, general and administrative (“SG&A”) expenses as a percent of sales for the three-month periods ended June 30, 2012 and 2011 were 18% and 15%, respectively. Actual costs in fiscal 2013 were $4,084, an increase of $383, or 10%, compared with the first quarter of fiscal 2012 SG&A of $3,701. The increase in SG&A expenses was primarily due to personnel additions to support growth in our business.

Interest income for the three month-periods ended June 30, 2012 and 2011 was $11 and $21, respectively. Low levels of interest income resulted from the continuing low level of interest rates on short term U.S. government securities and money market rates.

Interest expense was $80 for the quarter ended June 30, 2012, up from $20 for the quarter ended June 30, 2011. The increase was due to interest recorded relating to our uncertain tax positions.

The tax rate in the first quarter of fiscal 2013 was 33%, which compares with 34% in the same period last year. Included in the first quarter was a $24 charge to resolve a dispute with the IRS relating to research and development tax credits claimed during tax years 2009 and 2010.

Net income for the first three months of fiscal 2013 compared with the first three months of fiscal 2012 was $1,390 and $3,016, respectively. Income per diluted share was $0.14 and $0.30 for the respective periods.

22

Liquidity and Capital Resources

The following discussion should be read in conjunction with our Condensed Consolidated Statements of Cash Flows:

| June 30, 2012 |

March 31, 2012 |

|||||||

| Cash and investments |

$ | 46,624 | $ | 41,688 | ||||

| Working capital |

54,241 | 52,730 | ||||||

| Working capital ratio(1) |

3.6 | 3.2 | ||||||

| (1) | Working capital ratio equals current assets divided by current liabilities. |

Net cash generated by operating activities for the first quarter of fiscal 2013 was $5,477, compared with $1,588 used by operating activities for the first quarter of fiscal 2012. The increase in cash generated was due to improvements in unbilled revenue and accounts receivable, partly offset by lower customer deposits and lower net income.

Dividend payments and capital expenditures in the first quarter of fiscal 2013 were $200 and $300, respectively, compared with $198 and $340, respectively, for the first quarter of fiscal 2012.

Capital expenditures for fiscal 2013 are expected to be between $3,000 and $3,500. Approximately 68% of our fiscal 2013 capital expenditures are expected to be for machinery and equipment, with the remaining amounts to be used for information technology and other items.

Cash and investments were $46,624 on June 30, 2012 compared with $41,688 on March 31, 2012, up $4,936, or 12%.

We invest net cash generated from operations in excess of cash held for near-term needs in either a money market account or in U.S. government instruments, generally with maturity periods of up to 180 days. Our money market account is used to securitize our outstanding letters of credit and allows us to pay a lower cost on those letters of credit.

Our revolving credit facility with Bank of America, N.A. provides us with a line of credit of $25,000, including letters of credit and bank guarantees. In addition, the agreement allows us to increase the line of credit, at our discretion, up to another $25,000, for total availability of $50,000. Borrowings under our credit facility are secured by all of our assets. Letters of credit outstanding under our credit facility on June 30, 2012 and March 31, 2012 were $12,425 and $9,920, respectively. There were no other amounts outstanding on our credit facility at June 30, 2012 and March 31, 2012. Our borrowing rate as of June 30 and March 31, 2012 was Bank of America’s prime rate, or 3.25%. Availability under the line of credit was $12,575 at June 30, 2012. We believe that cash generated from operations, combined with our investments and available financing capacity under our credit facility, will be adequate to meet our cash needs for the immediate future.

Orders and Backlog

Orders for the three-month period ended June 30, 2012 were $19,721 compared with $19,043 for the same period last year, an increase of 4%. Orders represent written communications received from customers requesting us to supply products and services. Domestic orders were 41% of total orders, or $8,006, and international orders were 59% of total orders, or $11,715, in the current quarter compared with the first quarter of fiscal 2012, when domestic orders were 66%, or $12,654, of total orders, and international orders were 34%, or $6,389, of total orders.

23

Backlog was $91,980 at June 30, 2012, compared with $94,934 at March 31, 2012, a 3% decrease. Backlog is defined as the total dollar value of orders received for which revenue has not yet been recognized. All orders in backlog represent orders from our traditional markets in established product lines. Approximately 70% to 80% of orders currently in backlog are expected to be converted to sales within the next twelve months. This is lower than our normal conversion, which is approximately 85% to 90% over an upcoming 12-month period. The difference in our current backlog includes the carrier project for the U.S. Navy and two orders for new U.S. nuclear plants. These projects have a multi-year conversion cycle and significant stops and starts during the manufacturing process. At June 30, 2012, 30% of our backlog was attributable to equipment for refinery project work, 18% for chemical and petrochemical projects, 26% for power projects, including nuclear, and 26% for other industrial or commercial applications (including the carrier order for the U.S. Navy). At June 30, 2011, 30% of our backlog was attributed to equipment for refinery project work, 10% for chemical and petrochemical projects, 21% for power projects, and 39% for other industrial or commercial applications.

At June 30, 2012, one project with a value of $1,010 was on hold. The project was placed back on hold in the second quarter of fiscal 2012. This project was originally won in September 2008, placed on hold in November 2008 and removed from hold by the customer in October 2010. Although it had a scheduled delivery of December 2012, it has now been placed back on hold by the customer.

Outlook

We believe that we remain in the early stages of a recovery in the refinery and petrochemical markets. We also believe the improved strength of the alternative energy markets, including the nuclear market, will continue through fiscal 2013. We experienced significant order growth in the fourth quarter of fiscal 2012, with orders of $42,269, which was approximately double the average order level for each of the first three quarters. The first quarter of fiscal 2013 saw a drop in orders to $19,721 partly due to near-term timing of orders. Despite this reduction, we continue to see significant activity in our pipeline and remain optimistic that we will experience stronger order levels in the near future. Our backlog is $91,980, just 3% below our March 2012 level, which represented our record high at $94,934.

We expect revenue to increase to $105 to $115 million, a gain of 2-11%, in fiscal 2013. Approximately, 18% to 22% of our revenue is expected to come from Energy Steel. In fiscal 2012, Energy Steel contributed 17% of our revenue. In fiscal 2012, sales in the first half of the year were $58,607, while they decreased to $44,579 in the second half of the year. Conversely, in fiscal 2013, we expect stronger sales in the second half of the year compared with the first half of the fiscal year.

Normally, we convert 85% to 90% of our existing backlog to sales within a 12-month period. However, we have three large projects which are converting over a multi-year time period. Although the U.S. Navy project and two large projects for the new nuclear reactors being built in the southeast U.S. will partially convert in fiscal 2013, we expect all three projects to continue into subsequent fiscal years. These three projects make up approximately one third of our current backlog. Therefore, our June 30, 2012 backlog will extend beyond our historical conversion level. We expect to convert approximately 70% to 80% of our March 31, 2012 backlog to sales in fiscal 2013.

24

For fiscal 2013, we expect sales to be lower in the first half of the year than during the second half of the year. This is a result of the lower level of orders received in the first three quarters of fiscal 2012 relative to the stronger fourth quarter orders achieved in fiscal 2012. Our expected growth range for fiscal 2013 assumes conversion of backlog as well as continued market improvement and investment by our customers. The upper end of the range may be achieved by acceleration of projects by refining, petrochemical and alternative energy end users, our historical customer base. We believe increased focus on safety and redundancy projects at U.S. nuclear facilities may provide near term opportunities at Energy Steel. The U.S. Navy and two large nuclear projects are also expected to contribute significantly to sales in fiscal 2013. Any unexpected delay in any of these projects could negatively impact fiscal 2013 revenue and earnings.

We expect gross profit margin in fiscal 2013 to be in the 28% to 31% range. This margin level represents a decrease from the fiscal 2012 gross margin of 32%, which included some higher margin projects, especially in the first two quarters. Gross margin was 36% in the first half of fiscal 2012 and 26% in the second half of fiscal 2012. While we still have a few lower margin projects in our backlog, the overall margin within our backlog has improved over the past few quarters. We expect gross margins in the first half of fiscal 2013 to be comparable or slightly higher to the second half of fiscal 2012, with margin improvement in the second half of the fiscal year. We also believe that we are experiencing a shift of business in the refining and petrochemical market toward international markets, where margins are generally lower than domestic project margins. Moreover, we are investing in operations and engineering personnel to prepare for current and future growth opportunities.

Gross profit margins are expected to improve with anticipated volume increases, which are expected to occur during fiscal 2013 and beyond. Due to changes in geographic and end use market mix, we expect gross margins are unlikely to reach the 40% range achieved in the prior up cycle. We believe long term up cycle gross profit margin percentage in the mid-to-upper 30’s is a more realistic expectation. We also expect this recovery will continue to be more focused on emerging markets, which historically have lower margins and more competitive pricing than developed markets.

We believe achievement of the upper end of our margin projections can occur if we experience: (i) increased volume that utilizes excess capacity; (ii) continued improvements in our manufacturing productivity; and/or (iii) expanded margin opportunities at Energy Steel.

SG&A spending during fiscal 2013 is expected to be between 15%-16% of sales. We continue to invest in personnel as we prepare for increased opportunities in fiscal 2013 and beyond. Our effective tax rate during fiscal 2013 is expected to be between 34% and 35%.

Cash flow in fiscal 2013 is expected to be positive, driven primarily by net income, partly offset by capital spending as well as a minimal need for additional working capital.

Contingencies and Commitments

We have been named as a defendant in certain lawsuits alleging personal injury from exposure to asbestos contained in our products. We are a co-defendant with numerous other defendants in these lawsuits and intend to vigorously defend against these claims. The claims are similar to previous asbestos lawsuits that named us as a defendant. Such previous lawsuits either were dismissed when it was shown that we had not supplied products to the plaintiffs’ places of work or were settled by us for amounts below expected defense costs. Neither the outcome of these lawsuits nor the potential for liability can be determined at this time.

25

From time to time in the ordinary course of business, we are subject to legal proceedings and potential claims. As of June 30, 2012, other than noted above, we were unaware of any other material litigation matters.

Critical Accounting Policies, Estimates, and Judgments

Our unaudited condensed consolidated financial statements are based on the selection of accounting policies and the application of significant accounting estimates, some of which require management to make significant assumptions. We believe that the most critical accounting estimates used in the preparation of our condensed consolidated financial statements relate to labor hour estimates used to recognize revenue under the percentage-of-completion method, accounting for business combinations, goodwill and intangible asset impairment, accounting for income taxes, accounting for contingencies, under which we accrue a loss when it is probable that a liability has been incurred and the amount can be reasonably estimated, and accounting for pensions and other postretirement benefits. For further information, refer to Item 7 “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and Item 8 “Financial Statements and Supplementary Data” included in our Annual Report on Form 10-K for the year ended March 31, 2012.

Off Balance Sheet Arrangements

We did not have any off balance sheet arrangements as of June 30, 2012 or March 31, 2012, other than operating leases and letters of credit.

| Item 3. | Quantitative and Qualitative Disclosures About Market Risk |

The principal market risks (i.e., the risk of loss arising from changes in the market) to which we are exposed are foreign currency exchange rates, price risk and project cancellation risk.

The assumptions applied in preparing the following qualitative and quantitative disclosures regarding foreign currency exchange rate, price risk and project cancellation risk are based upon volatility ranges experienced by us in relevant historical periods, our current knowledge of the marketplace, and our judgment of the probability of future volatility based upon the historical trends and economic conditions of the markets in which we operate.

Foreign Currency

International consolidated sales for the first quarter of fiscal 2012 were 44% of total sales compared with 55% for the same period of fiscal 2011. Operating in markets throughout the world exposes us to movements in currency exchange rates. Currency movements can affect sales in several ways, the foremost being our ability to compete for orders against foreign competitors that base their prices on relatively weaker currencies. Business lost due to competition for orders against competitors using a relatively weaker currency cannot be quantified. In addition, cash can be adversely impacted by the conversion of sales made by us in a foreign currency to U.S. dollars. In the first quarter of each of fiscal 2012 and fiscal 2011, all sales by us and our wholly-owned subsidiaries, for which we were paid, were denominated in the local currency (U.S. dollars or Chinese RMB). At certain times, we may enter into forward foreign currency exchange agreements to hedge our exposure against potential unfavorable changes in foreign currency values on significant sales contracts negotiated in foreign currencies.

26

We have limited exposure to foreign currency purchases. In the first quarter of fiscal 2013 and 2012, our purchases in foreign currencies represented 1% and 1%, respectively, of the cost of products sold. At certain times, we may utilize forward foreign currency exchange contracts to limit currency exposure. Forward foreign currency exchange contracts were not used in the periods being reported on in this Quarterly Report on Form 10-Q and as of June 30, 2012 and March 31, 2012, we held no forward foreign currency contracts.

Price Risk

Operating in a global marketplace requires us to compete with other global manufacturers which, in some instances, benefit from lower production costs and more favorable economic conditions. Although we believe that our customers differentiate our products on the basis of our manufacturing quality and engineering experience and excellence, among other things, such lower production costs and more favorable economic conditions mean that certain of our competitors are able to offer products similar to ours at lower prices. Moreover, the cost of metals and other materials used in our products have experienced significant volatility. Such factors, in addition to the global effects of the recent volatility and disruption of the capital and credit markets, have resulted in downward demand and pricing pressure on our products.

Project Cancellation and Project Continuation Risk

Open orders are reviewed continuously through communications with customers. If it becomes evident to us that a project is delayed well beyond its original shipment date, management will move the project into “placed on hold” (i.e., suspended) category. Furthermore, if a project is cancelled by our customer, it is removed from our backlog.

Economic conditions over the past few years have led to a higher likelihood of project cancellation by our customers. At June 30, 2012, one project with a value of $1,010 was on hold. We attempt to mitigate the risk of cancellation by structuring contracts with our customers to maximize the likelihood that progress payments made to us for individual projects cover the costs we have incurred. As a result, we do not believe we have a significant cash exposure to projects which may be cancelled.

| Item 4. | Controls and Procedures |

Conclusion regarding the effectiveness of disclosure controls and procedures

Our President and Chief Executive Officer (principal executive officer) and Vice President-Finance & Administration and Chief Financial Officer (principal financial officer) each have evaluated the effectiveness of our disclosure controls and procedures (as defined in Exchange Act Rules 13a-15(e) and 15d-15(e)) as of the end of the period covered by this Quarterly Report on Form 10-Q. Based on such evaluation, and as of such date, our President and Chief Executive Officer and Vice President-Finance & Administration and Chief Financial Officer concluded that our disclosure controls and procedures were effective in all material respects.

Changes in internal control over financial reporting

There has been no change to our internal control over financial reporting during the quarter covered by this Quarterly Report on Form 10-Q that has materially affected, or that is reasonably likely to materially affect our internal control over financial reporting.

27

GRAHAM CORPORATION AND SUBSIDIARIES

FORM 10-Q

June 30, 2012

PART II - OTHER INFORMATION

| Item 5. | Other Information |

The below disclosure is being made pursuant to the instruction contained in Item 5 of Form 10-Q. The item numbers below refer to the applicable Current Report on Form 8-K Item numbers.

Item 5.02. Departure of Directors or Certain Officers; Election of Directors; Appointment of Certain Officers; Compensatory Arrangements of Certain Officers.

On July 25, 2012, the Compensation Committee of the Board of Directors approved increases to the base salaries of our named executive officers, as follows:

| Named Executive Officer | Previous Base Salary |

New Base Salary |

||||||

| James R. Lines, |

$ | 292,778 | $ | 340,000 | ||||

| Jeff Glajch, |

$ | 229,473 | $ | 240,000 | ||||

| Alan Smith, |

$ | 194,713 | $ | 205,000 | ||||

| Robert A. Platt |

$ | 163,000 | $ | 175,000 | ||||

| Jennifer Condame, |

$ | 140,689 | $ | 150,000 | ||||

Item 5.07 Submission of Matters to a Vote of Security Holders.

At the Annual Meeting of Stockholders held on July 26, 2012, our stockholders voted on the matters described below.

| 1. | Our stockholders elected three directors, each for a three year term expiring in 2015. The number of shares that: (i) voted for the election of each such director; (ii) withheld authority to vote for each such director; and (iii) represented broker non-votes with respect to each such director is summarized in the table below. |

| Director Nominee |

Votes For | Votes Withheld | Broker Non-Votes* | |||||||||

| Helen H. Berkeley |

6,851,303 | 120,195 | 1,804,347 | |||||||||

| Alan Fortier |

6,869,784 | 101,714 | 1,804,347 | |||||||||

| James R. Lines |

6,869,406 | 102,092 | 1,804,347 | |||||||||

28

| 2. | On an advisory basis, our stockholders approved the compensation of the our named executive officers as such compensation information is disclosed in our definitive proxy statement filed with the Securities and Exchange Commission on June 18, 2012, including the Compensation Discussion and Analysis, compensation tables and other narrative disclosures included therein. The table below summarizes the number of shares that voted for, against and abstained from voting on the compensation of our named executive officers, as well as the number of shares representing broker non-votes with respect to such advisory vote. |

| Votes For |

Votes Against |

Abstentions |

Broker Non-Votes* | |||

| 6,778,783 | 100,768 | 91,947 | 1,804,347 |

| 3. | Our stockholders ratified the selection of Deloitte & Touche LLP as our independent registered public accounting firm for the fiscal year ending March 31, 2013. The number of shares that voted for, against and abstained from voting for the ratification of the selection of Deloitte & Touche LLP as our independent registered public accounting firm for the fiscal year ending March 31, 2013 is summarized in the table below. |

| Votes For |

Votes Against |

Abstentions | ||

| 8,701,273 | 45,125 | 29,447 |

| * | Broker non-votes represent shares held by broker nominees for beneficial owners that were not voted with respect to a non-routine proposal because the broker nominee did not receive voting instructions from the beneficial owner and lacked discretionary authority to vote the shares. If a broker does not receive voting instructions from the beneficial owner, a broker may vote on routine matters but may not vote on non-routine matters. Broker non-votes are counted for the purpose of determining the presence of a quorum but are not counted for the purpose of determining the number of shares entitled to vote on non-routine matters such as an election of directors and the advisory vote on our named executive officer compensation. |

Item 8.01 Other Events.

On July 26, 2012 the Board of Directors extended our existing stock repurchase program. The stock repurchase program, as extended, permits us to repurchase up to 1,000,000 shares of our Common Stock either in the open market or through privately negotiated transactions and terminates at the earlier of the expiration of the program on July 29, 2013, when all 1,000,000 shares have been repurchased or when the Board of Directors terminates the program. We intend to use cash on hand to fund any stock repurchases under the program. 623,000 shares of Common Stock remain available for repurchase under the stock repurchase program.

29

| Item 6. | Exhibits |